Find out all about the different material streams

Search

REMONDIS’ business locations around the world

Being one of the world’s leading recycling, service and water companies, REMONDIS has around 1,000 business locations across the globe. These can be found in over 30 countries in Europe, Africa, Asia and Australia.

REMONDIS’ business locations in Germany

REMONDIS’ business activities in Germany are managed and carried out by its six regional companies. REMONDIS also has a whole variety of specialist companies, many of which are based here in Germany as well.

In principle – from a technological point of view – practically everything can be recycled. However, depending on the complexity of the mixture of the substances, it can be very complicated to process them as it may be very difficult to separate the individual materials from each other.

The conflict between what’s possible and what’s profitable

Large investments have to be made in specialist machinery for recycling to work properly. If there are not enough customers willing to buy the recycled raw materials, then it might mean that it is simply not profitable to recycle certain products and this work is not carried out. This may be a shame for the environment; it is, however, unfortunately an economic reality. All the more reason, therefore, for setting up political framework conditions to counteract this dilemma. For example, by creating grants to make it more worthwhile for companies to invest in recycling technologies or by introducing minimum recycled content mandates for industry to make it obligatory for manufacturers to use recycled raw materials in their new products.

Improving the range and quality of recovered materials

REMONDIS constantly does everything in its power to recycle ever more materials ever more efficiently. And it not only does this to meet the steadily increasing recycling standards, such as those set out in the new Packaging Law. It primarily does this of its own accord. At the end of the day, every additional gram of recyclable material recovered helps curb climate change and conserve natural resources. Our new high performance sorting facility in Erftstadt is an excellent example of how a willingness to innovate can lead to new forms of recycling. Every year, this plant sends on 120,000 tonnes of material for recycling – primarily plastics but also aluminium, paper and even glass. By deploying state-of-the-art technologies, we have improved the range and quality of the recovered materials – reaching levels that no other facility has managed to achieve. This means that we have not only succeeded in separating and recovering recyclables according to type but also according to the smallest of subcategories (for example into different types of plastics). This, in turn, means that a whole range of different quality recycled raw materials can be produced.

Even outthrow materials can be filtered out and recovered according to type. Ultimately, practically all of the input material can be recycled for reuse.

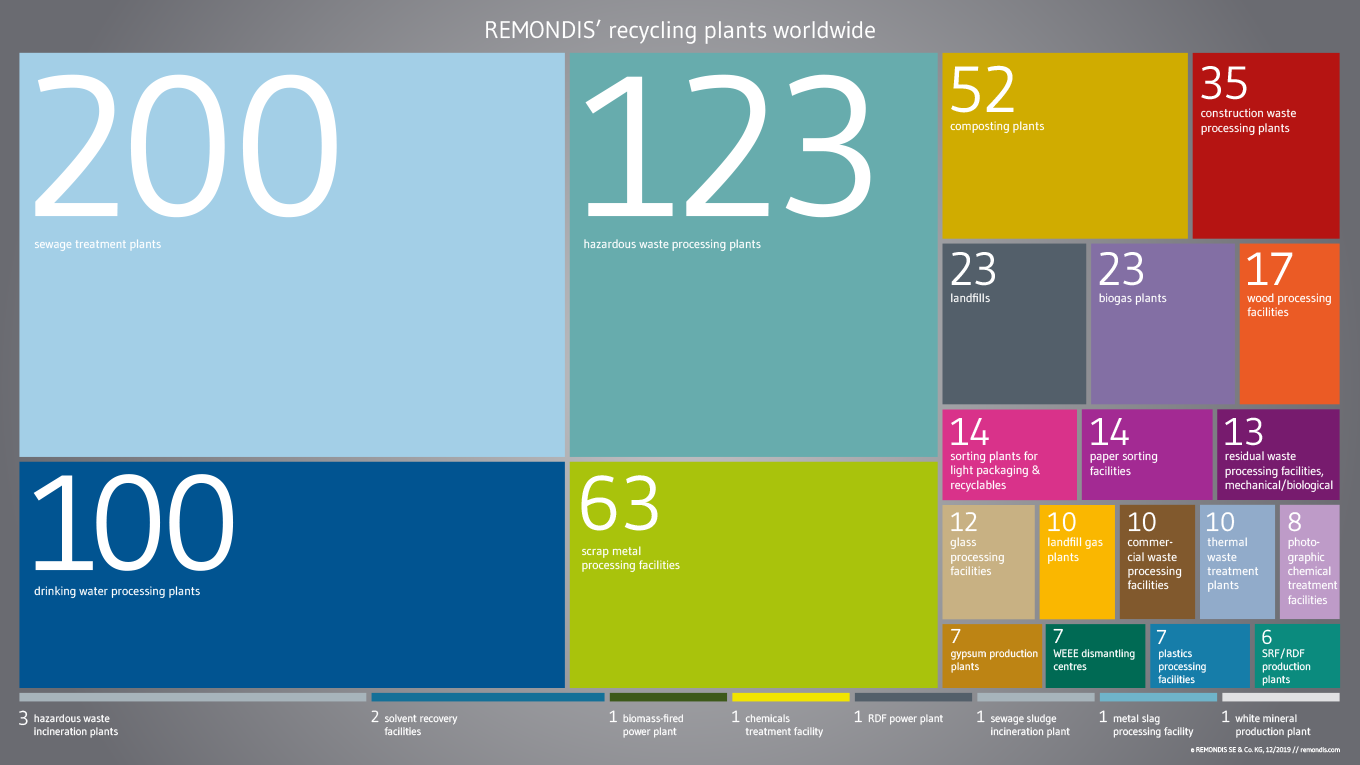

The extensive capacities of the REMONDIS Group

Climate action and resource protection are holistic tasks that include recovering preferably all of the recyclables that are currently in circulation so they can be reused. From biomass all the way through to technology metals. Which is why we operate processing facilities within the REMONDIS Group that are capable of handling a whole range of different materials and separating substances that, at first glance, would appear to be impossible to recover. We have, for example, developed a patented process called TetraPhos® to extract phosphorus (a vital substance for all living beings that is impossible to substitute) from sewage sludge ash so that it can be returned to production cycles.

The TetraPhos® process has already been implemented on a large scale in Germany by the public private partnership between the Free and Hanseatic City of Hamburg and REMONDIS.

The technologies of the future. Being researched by us today

We collaborate closely with researchers and scientists to further extend and improve our recycling capacities. This often involves trying to recover recyclables from products that, up to now, have been impossible to remove or that has been done poorly. Here are just two examples of projects that REMONDIS is currently involved in.

Recycling fibre-reinforced plastics

Carbon fibre reinforced polymers (CFRPs) have a whole host of advantages. They are, above all, lightweight and yet extremely robust making them the perfect material for the automobile industry. However, they also have one big disadvantage: the mix of material is so complex that it is extremely difficult to recycle. This is a real problem for car manufacturers who are legally obliged to produce vehicles that are 95% recyclable. A number of partners from the worlds of industry and science are now working together on a research project to tackle this problem. This project is looking to develop a production and recycling strategy for electromobility to enable lightweight components in fibre-reinforced composite hybrid structures to be recycled for reuse and is known as ReLei1, an abbreviation of its German title (Fertigungs- und Recyclingstrategie für die Elektromobilität zur stofflichen Verwertung von Leichtbaustrukturen in Faserkunststoffverbund-Hybridbauweise). Using the rear shelf of a car as an example, this project aims to show how CFRPs can be processed and reused. The dismantling and treatment process has created a number of products including plastic recyclates suitable for injection moulding and recycled fleece, both of which can be reused immediately by the car production plant. The following lists the individual measures carried out during the research project:

ReLei is being supported as a joint project by the Federal Ministry of Education and Research (BMBF)*

Material preparation work

Analysing the existing technologies currently being used to prepare and bind hybrid lightweight components

Analysing ways of recycling fibre-reinforced plastic components

Developing processes to recover secondary fibres and process them into semi-finished non-woven fabric

Extending and adapting existing processing technologies to produce recycled material that can be used for injection moulding

Characterising the materials to evaluate the way recycling changes the properties of a material

Production processes

Developing a novel foam moulding process to produce complex-shaped thermoplastic sandwich structures

Constructing a multifunctional experimental tool to produce test pieces and carry out parameter studies

Developing a simulation strategy to illustrate the foam moulding process

Treating secondary materials using the foam moulding process

Developing, designing, producing and testing the complex demonstrator structure

Dismantling & binding technology

Analysing and identifying dismantling-friendly techniques for binding and separating hybrid lightweight structures

Developing dismantling-friendly binding processes for producing new kinds of bodywork for electric vehicles

Developing a ‘smart tool’ concept to enable an automated and resource-friendly dismantling process

*The ReLei research and development project has received funds from the Federal Ministry of Education and Research (BMBF) as part of its ‘Innovations for the production, services and work of tomorrow’ concept (funding code: 02PJ2760 – 02PJ2763) as well as funds from the Energy and Climate Fund and is being coordinated by the project management agency, PTKA in Karlsruhe. The author is responsible for the published content.

Real-time detection of metals

Residual materials can contain a variety of different substances including very small amounts of precious metals and other types of metal that, up to now, have mostly not been recovered for reuse. ARGOS, a joint research project between the circular economy and the world of science, is aiming to change this. A real-time system has been developed that enables specific metals to be tracked down – even the smallest amounts. This involves genuine detective work based on sensor-based particle characterisation, mathematical derivatives and empirically observed material stream properties. The whole project has been implemented with the IME Process Metallurgy and Metal Recycling Institute at RWTH Aachen University.